Hydrogen Bunkering Methods

Four approaches to refueling hydrogen-powered vessels—from fixed installations to innovative container swapping systems

Maritime hydrogen bunkering remains in its infancy, with infrastructure developing alongside the first generation of hydrogen-powered vessels. Unlike conventional marine fuels with established global supply chains, hydrogen bunkering requires purpose-built solutions tailored to the fuel’s unique physical properties—whether stored as compressed gas at 350–700 bar or as cryogenic liquid at -253°C.

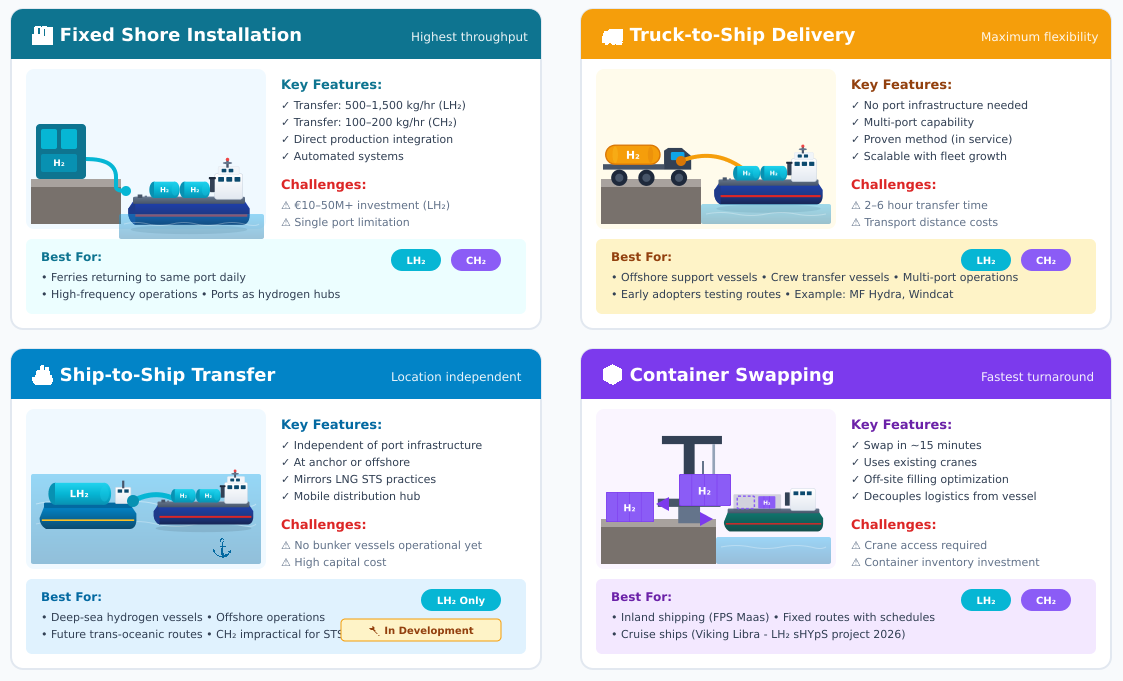

Four distinct bunkering approaches have emerged, each offering different trade-offs between infrastructure investment, operational flexibility, and transfer efficiency. The optimal choice depends on vessel type, route patterns, and the maturity of hydrogen supply at specific ports.

Bunkering Methods at a Glance

| Method | H₂ Form | Location Flexibility | Transfer Speed | Infrastructure Cost | Best Suited For |

|---|---|---|---|---|---|

| Fixed Shore Installation | CH₂ LH₂ | Low—single port | Fastest | High | Ferries, regular routes |

| Truck-to-Ship | CH₂ LH₂ | High—any accessible quay | Moderate | Low | Multi-port operations, early adopters |

| Ship-to-Ship | LH₂ | Very high—at anchor/offshore | Moderate–Fast | Medium–High | Deep-sea vessels, offshore operations |

| Container Swapping | CH₂ LH₂ | Medium—crane-equipped ports | Very fast (swap only) | Medium | Inland shipping, fixed routes |

Note: Transfer speeds and costs vary significantly based on specific equipment, pressure differentials, and local conditions. Values shown are general guidance.

Explore Each Method

Safety & Regulatory Framework

Hydrogen bunkering safety builds on decades of industrial hydrogen handling experience, adapted for the marine environment. International standards are evolving rapidly as operational experience accumulates.

Key Safety Considerations

Universal Requirements

- Hazardous area classification and ventilation

- Gas detection and emergency shutdown systems

- Grounding and bonding for static discharge

- Exclusion zones during transfer operations

- Trained personnel with hydrogen-specific certification

Current & Planned Bunkering Infrastructure

🗺️

Interactive Map: Hydrogen Bunkering Locations

View operational and planned bunkering facilities across Europe

See also: H₂ Liquefaction Facilities Map for upstream supply infrastructure critical to LH₂ bunkering availability.